Vellerand is continuously investing in new machinery to improve the available technological solutions.

To be more flexible with regards to production of small series of exhausts and other products, we have obtained Trumpf TruMark Station 7000, allowing us to mark different materials, like metals and most plastics.

With its large interior dimensions, the TruMark Station 7000 marking system offers a great amount of space for almost any application. It is possible to mark single large components, components weighing up to 50 kg with laser precision, or a large number of small parts for production.

The machine allows you to mark on a plane surface or cylinder using a rotary axis.

Suitable materials are metals and most plastics.

Max detail dimensions: 960x375x290mm.

The maximum area that can be marked at one time is 130x130mm.

Max part weight: 50kg on the desktop

20 kg on the pivot axis

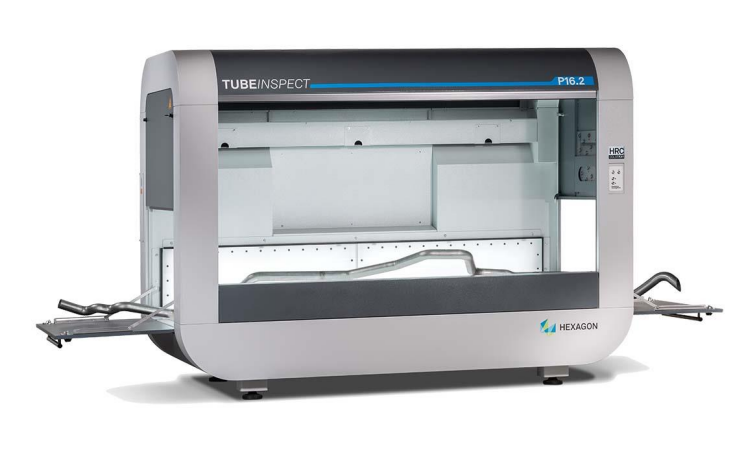

In addition we have a new measuring machine Tubeinspect P16.2, which stands for efficient quality assurance in tube manufacturing and can be deployed as an optical tube measuring system and programmable optical gage. We have implemented it in the production cycle, to improve the time for setting up and correcting bending programs as well as reverse engineering of sample tubes and initial sample testing.

| Tubeinspect P16.2 | |

| Measuring area | 2600 mm x 1250 mm x 700 mm |

| Cameras | 16 high-resolution digital cameras with GigE-technology |

| Tube diameter | 3.0 mm – 200 mm |

| Bending angle | 1⁰ – 340⁰ |

| Accuracy | 0.085 mm sheath tolerance (1 Sigma) |