Vellerand is an established manufacturer of automotive and industrial equipment, with expertise in both aftersales and original equipment. With its’ steady growth, the family company Vellerand has expanded its reach to also other industries like metal furniture and warehouse equipment, as well as smart parcel lockers, creating a platform for innovation.

The company, Universal Industries established in Estonia, started back in 1987, a small-scale production in a workshop and shortly found its way to automotive industry, as in 1993 already started with industrial production of exhaust pipes and parts.

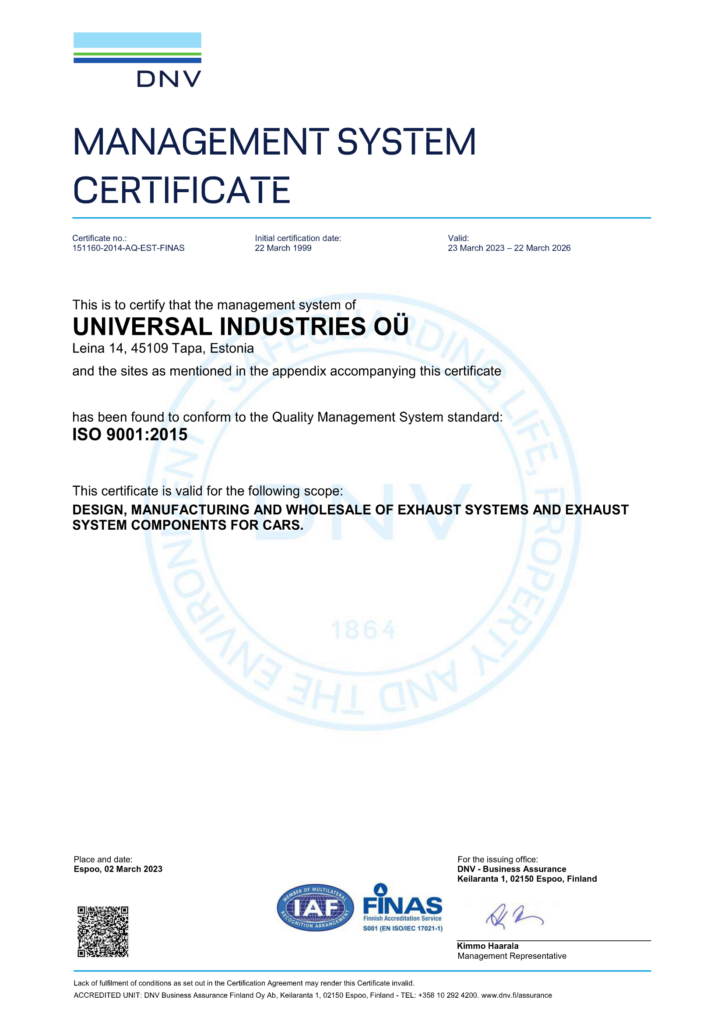

As quality has always been the top priority of the company, in 1999 ISO quality management system was introduced, and to this day is meeting the requirements of ISO 9001 certificate.

Universal Industries began using its trademark Vellerand in 2012, the name of the brand derives from the creator and CEO of the company – Mr. Jüri Vellerand, proud to stand behind his name, to guarantee the persistent quest for ever improving quality and innovation.

The company has been focused on continuous improvement to the production process, as well as increasing the product range and has targeted its investments towards enhancing production technologies. Cost-effective production and continuous R&D activities have enabled the company to remain competitive and gain reputation in the field. We offer our customers professional solutions – from design to elaborate end-products.

Due to our high-quality standards, we export over 98% of our products. Each year, the company has managed to top the figures of the last years, giving insight into good management decisions and prosperous partnerships with its clients.

With extensive experience of producing both AM and OEM exhaust systems in Europe, Vellerand is an accomplished and leading producer of quality mufflers for the EU market, with a wide range of models for all car makes and models. From the accumulated knowledge of the OE projects, the exhausts meet the demands of the all the legal requirements as well as the needs of the most demanding clients.

We are one of the few companies on the EU market, who produce pressed boxes in-house. The pressed box mufflers benefit lies in the optimised noise and back-pressure, keeping your car in prime condition, as well as technical measures, such as meeting the ideal capacity and best-fit for the exhaust systems. The in-house production helps us supply high-end long-lasting exhaust systems, for an affordable price.

Automation is key in a stable and excellent production quality. We use automated 2D and 3D laser cutting, robot welding machinery, hydraulic presses and other extensive unmanned processes, to advance our production speed and standards.

Furthermore, our in-house development team continuously develops new exhaust systems into our range. Part of value chain, R&D so close to home, we can swiftly develop and respond to any changes on the market, always offering the latest models and widest range possible.

All exhausts are made from aluminized or stainless steel and designed for a guaranteed perfect fit. The exhausts are produced following the ISO 9001:2015 standards.

To build trust and meet the international regulations, all the noise and fitting tests are performed in Germany, by TÜV SÜD Auto Service GmbH.